In the dynamic landscape of manufacturing, efficiency, accuracy, and agility are paramount. In the quest for operational excellence, Enterprise Resource Planning (ERP) systems have emerged as indispensable tools for manufacturers worldwide. These integrated software solutions streamline and optimize a multitude of processes across various departments, offering a plethora of benefits that significantly impact the bottom line.

Let’s delve into the importance of ERP systems for manufacturers.

1. Centralized Data Management

One of the primary advantages of ERP systems lies in their ability to centralize data management. Manufacturing operations generate vast amounts of data daily, ranging from inventory levels and production schedules to supply chain logistics and financial transactions. ERP systems serve as centralized repositories, housing all critical information in one accessible location. This consolidation minimizes data silos, enhances data accuracy, and facilitates real-time decision-making processes.

2. Enhanced Efficiency and Productivity

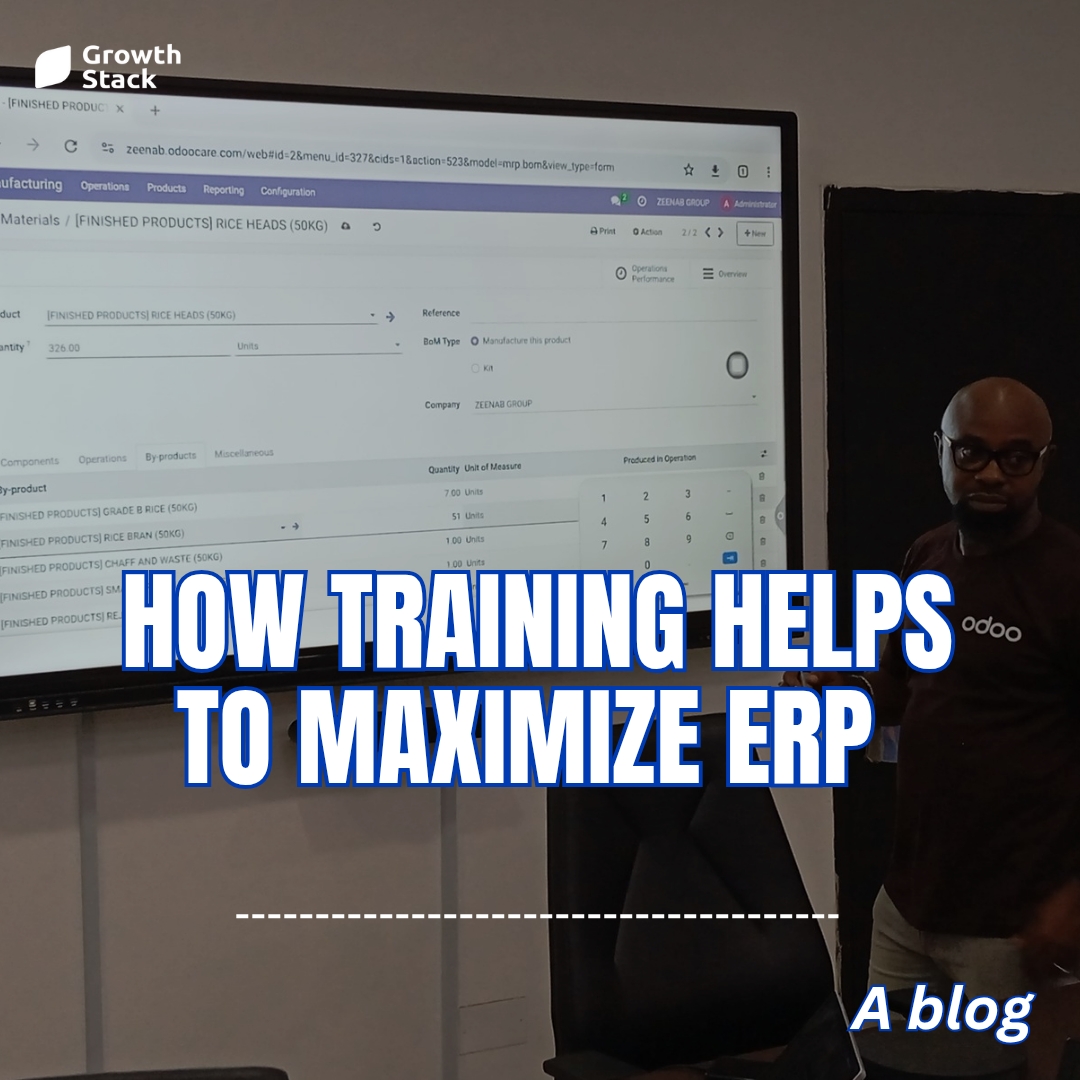

Efficiency and productivity are the lifeblood of manufacturing operations. ERP systems automate routine tasks, streamline workflows, and eliminate manual processes prone to errors and delays. By integrating disparate functions such as production planning, inventory management, procurement, and order fulfillment, ERP systems optimize resource utilization, reduce lead times, and enhance overall operational efficiency. Employees can focus their efforts on value-added activities, driving productivity gains across the organization.

3. Improved Inventory Management

Effective inventory management is pivotal for manufacturers to meet customer demands while minimizing carrying costs and stockouts. ERP systems provide real-time visibility into inventory levels, demand forecasts, and supplier lead times, enabling proactive inventory control and optimization. With features like automatic reorder points, just-in-time inventory replenishment, and inventory tracking, manufacturers can achieve optimal inventory levels, reduce excess stock, and mitigate the risks of stockouts and production disruptions.

4. Regulatory Compliance and Risk Mitigation

Manufacturers operate in a highly regulated environment, subject to a myriad of industry standards, government regulations, and compliance mandates.

ERP systems incorporate robust compliance frameworks and audit trails to ensure adherence to regulatory requirements such as ISO standards, FDA regulations, and environmental guidelines. By standardizing processes, documenting procedures, and enforcing compliance controls, ERP systems mitigate regulatory risks, avoid costly penalties, and uphold corporate integrity and reputation.

Conclusion

Enterprise Resource Planning (ERP) systems are indispensable assets for manufacturers seeking to thrive in today’s competitive landscape.

By centralizing data management, enhancing efficiency, optimizing inventory, streamlining supply chain operations, enabling data-driven decision-making, and ensuring regulatory compliance, ERP systems serve as catalysts for operational excellence and sustainable growth.

Manufacturers that embrace ERP solutions stand poised to unlock new levels of productivity, agility, and profitability in an ever-evolving marketplace.

Growth Stack, an ERP implementation and software development company with experience spanning over a decade is at the forefront to help you achieve your manufacturing goal.

We do this with tailor-made solutions for your case because we know in manufacturing, no one size fits all.